ISO 13485 Certified Medical Device Manufacturing Services

Expert Lifecycle Management of Life-Sustaining Devices

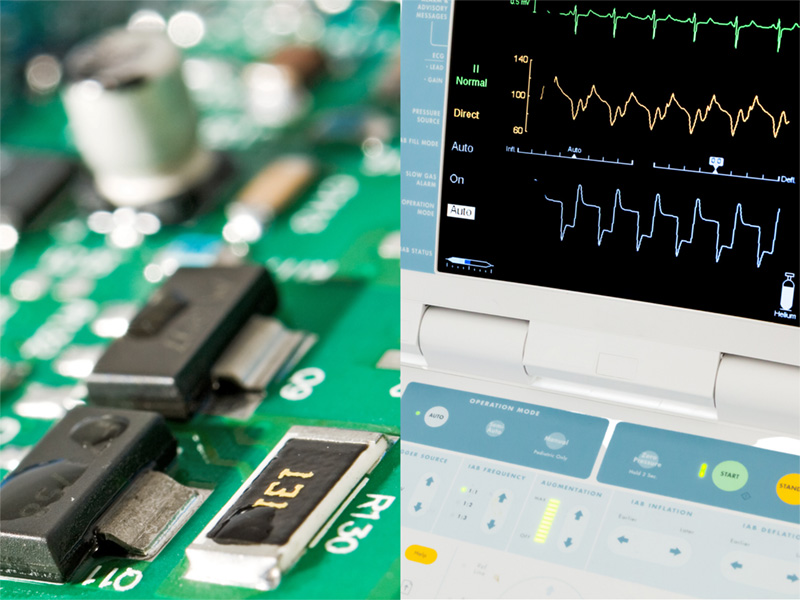

Medical device manufacturing projects carry unique requirements including multi-disciplinary development, technical engineering, regulatory compliance, risk management and experience with every stage of the product lifecycle. At Spartronics, we ensure that every customer benefits from dedicated technical support staff experienced in developing and manufacturing FDA-cleared medical devices. Reliability, quality, traceability and document control are central to each medical device and product we manufacture.

ISO 13485 Certified Medical Device Manufacturing Services You Can Trust

Spartronics proudly delivers ISO 13485 Certified Medical Device Manufacturing Services to ensure our clients’ devices meet the most stringent international standards for safety and efficacy. Our certified processes and validated systems support full compliance with regulatory frameworks such as FDA 21-CFR820 and international quality requirements across all device classes.

The customer partnerships we create are what differentiate us at Spartronics. Our customer-focused teams ensure transparency and efficiency throughout the product lifecycle. With a dedicated team, we support our customers from manufacturing readiness procedures, process validations and test strategies through the supply chain. Our unique approach ensures cost efficiency, risk management and on-time delivery of your medical device, built to specification and optimal quality.

Full Lifecycle ISO 13485 Support

From design transfer to post-market support, our ISO 13485 Certified Medical Device Manufacturing Services span every phase of the device lifecycle. We help clients reduce time to market while ensuring consistent, validated processes and full traceability for every critical component.

Centers of Excellence and Quality Certifications

The medical devices that we contract manufacture range in complexity through FDA Classes I, II & III. We offer centers of excellence that are FDA-registered facilities meeting all FDA-regulated standards for the engineering and contract manufacturing of life-sustaining and critical-care devices.

- 21-CFR820

- FDA/QSR Registered Class I, II and III

- IEC 60601-1

- ISO 9001:2015

- ISO 13485:2016

- ISO Class 8

- RoHS and REACH

- MDSAP

Medical Device Manufacturing in FDA-Registered, ISO 13485-Certified Facilities

Each of our facilities adheres to ISO 13485 standards and FDA Quality System Regulations, delivering the highest levels of quality assurance and patient safety for critical medical devices.

Applications Overview

Our customers rely on our strategic and technical expertise to drive product improvements, positively impact speed-to-market and revenue, while leading innovation across, or at any stage in, the product lifecycle. The highly complex, life-changing medical devices we build consistently meet the highest standards — ultimately improving the outcomes and lives of patients across the globe.

Building Tomorrow’s Medical Innovations

Spartronics' ISO 13485 Certified Medical Device Manufacturing Services enable innovation across a wide range of clinical and diagnostic fields, from neurostimulation to molecular diagnostics and beyond.

- Advanced Wound Care

- Biopsy Systems

- Cognitive Assessment

- Cosmetic Surgery

- Covid Testing Devices

- Diagnostics: Cancer, Cardiovascular, In Vitro, Molecular, POC

- DNA Sequencing

- Electrosurgical Generators

- Hearing Aid Devices

- Infusion

- Intraosseous Devices

- Medical Imaging

- Medical Simulation

- Monitoring: Cardiac, Intraoperative, Remote, Vital Signs

- Neurostimulation

- Ophthalmological Devices

- Orthopedic Devices

- Precision Measuring

- Research Instrumentation

- Respiratory

- Surgical Ablation Devices

- Therapeutic Devices

- Women’s Healthcare

- Advanced Wound Care

- Biopsy Systems

- Cognitive Assessment

- Cosmetic Surgery

- Covid Testing Devices

- Diagnostics: Cancer, Cardiovascular, In Vitro, Molecular, POC

- DNA Sequencing

- Electrosurgical Generators

- Hearing Aid Devices

- Infusion

- Intraosseous Devices

- Medical Imaging

- Medical Simulation

- Monitoring: Cardiac, Intraoperative, Remote, Vital Signs

- Neurostimulation

- Ophthalmological Devices

- Orthopedic Devices

- Precision Measuring

- Research Instrumentation

- Respiratory

- Surgical Ablation Devices

- Therapeutic Devices

- Women’s Healthcare

Product & Services Detail

Spartronics delivers superior quality medical products and customer support at every stage in the product lifecycle. Our advanced capabilities include printed circuit board assemblies (PCBA), sub-assemblies and finished products. Our sub-assembly services included specialized conformal coating, inspection and test coverage — to precision secondary operations. In addition, for finished medical devices we offer depot decontamination in repair, logistics services, loaner tool management and more.

End-to-End ISO 13485 Compliant Manufacturing

Whether you require PCBA assembly or full product box builds, our ISO 13485 Certified Medical Device Manufacturing Services ensure quality at every stage. We integrate strict process controls, validated tooling, and meticulous documentation to support your regulatory and operational goals.